Difference between revisions of "Directed Evolution and Synthetic Biology - Hunter Stone"

(→The Theory of Directed Evolution) |

(→Introduction - The Problem of Pathway Optimization) |

||

| Line 4: | Line 4: | ||

| − | ==Introduction - The Problem of | + | ==Introduction - The Problem of Optimization== |

| − | Researcher Jay Keasling has recently described a genetically-modified yeast strain that produces artemisinic acid, a chemical precursor to the antimalarial drug artemisinin. In these experiments, his team engineered yeast cells to express enzymes in a pathway that converts farnesyl pyrophosphate (FPP), a metabolic intermediate naturally occurring in yeast, into the desired product. However, in order to make this pathway generate a desirable amount of product, his team also had to tweak the existing yeast metabolism to ensure enough FPP was produced to channel through the synthetic pathway. In these manipulations, Keasling’s team was addressing a problem that faces many projects in synthetic biology, especially those aimed at producing a specific product: | + | Researcher Jay Keasling has recently described a genetically-modified yeast strain that produces artemisinic acid, a chemical precursor to the antimalarial drug artemisinin. In these experiments, his team engineered yeast cells to express enzymes in a pathway that converts farnesyl pyrophosphate (FPP), a metabolic intermediate naturally occurring in yeast, into the desired product. However, in order to make this pathway generate a desirable amount of product, his team also had to tweak the existing yeast metabolism to ensure enough FPP was produced to channel through the synthetic pathway. In these manipulations, Keasling’s team was addressing a problem that faces many projects in synthetic biology, especially those aimed at producing a specific product: optimization. Although we are increasingly able to build sophisticated constructs within living cells, the existence of these frameworks does not always correspond with their ability to fulfill their intended purposes efficiently and effectively. |

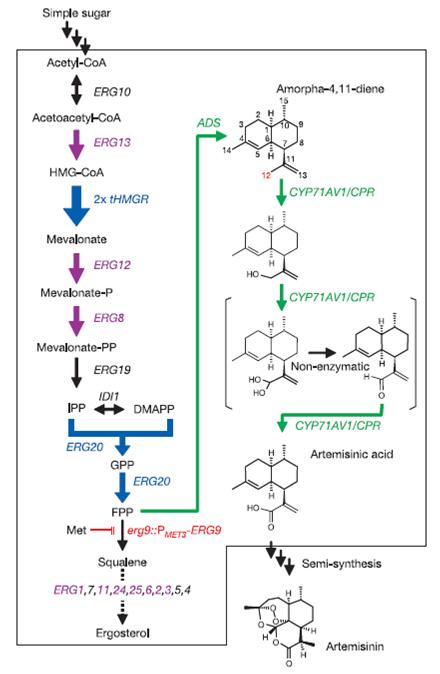

To maximize the amount of FPP produced, Keasling’s team increased the expression levels of the enzymes in the mevalonte pathway ('''Fig. 1'''). He also directed FPP away from the sterol biosynthetic pathway by repressing the enzyme responsible for conversion of FPP to squalene ('''Fig. 1'''). Although their methods were effective in producing desired products, the optimization of this biosynthetic pathway was limited only to augmenting the expression levels to only the known elements in the mevalonate pathway. Indeed, the researchers indicated that the yeast strain they developed requires furthers optimization to make the drug production system more commercially feasible. What other changes to the yeast strain could enhance product formation? Were the expression levels the researchers chose truly the best for meeting their goals? Could additional changes to other pathways or protein-protein interactions have lead to increases in product formation or decreases in product consumption? Could the enzymes themselves be more efficient in their catalytic activities? | To maximize the amount of FPP produced, Keasling’s team increased the expression levels of the enzymes in the mevalonte pathway ('''Fig. 1'''). He also directed FPP away from the sterol biosynthetic pathway by repressing the enzyme responsible for conversion of FPP to squalene ('''Fig. 1'''). Although their methods were effective in producing desired products, the optimization of this biosynthetic pathway was limited only to augmenting the expression levels to only the known elements in the mevalonate pathway. Indeed, the researchers indicated that the yeast strain they developed requires furthers optimization to make the drug production system more commercially feasible. What other changes to the yeast strain could enhance product formation? Were the expression levels the researchers chose truly the best for meeting their goals? Could additional changes to other pathways or protein-protein interactions have lead to increases in product formation or decreases in product consumption? Could the enzymes themselves be more efficient in their catalytic activities? | ||

Revision as of 19:12, 2 December 2007

Contents

- 1 Project Proposal

- 2 Introduction - The Problem of Optimization

- 3 The Theory of Directed Evolution

- 4 Proof of Concept: Directed Evolution vs. Rational Modeling in Lycopene-producing E. coli

- 5 Increases in Sophistication: Three Examples of Directed Evolution Showing Promise for Synthetic Biology

- 6 Works Cited

Project Proposal

My project will focus on attempts to utilize random mutations for optimization of synthetic pathways. Mathematical modeling of synthetic pathways is a powerful, proven tool to maximize product output. However, authors have recently shown that recombinant methods can be used to discover previously unknown elements of cell metabolism that will increase product yield even further. These methods of directed evolution have also been used to create powerful tools like promoters of specific expression levels, further increasing the relevance and importance of these methods to synthetic biology.

Introduction - The Problem of Optimization

Researcher Jay Keasling has recently described a genetically-modified yeast strain that produces artemisinic acid, a chemical precursor to the antimalarial drug artemisinin. In these experiments, his team engineered yeast cells to express enzymes in a pathway that converts farnesyl pyrophosphate (FPP), a metabolic intermediate naturally occurring in yeast, into the desired product. However, in order to make this pathway generate a desirable amount of product, his team also had to tweak the existing yeast metabolism to ensure enough FPP was produced to channel through the synthetic pathway. In these manipulations, Keasling’s team was addressing a problem that faces many projects in synthetic biology, especially those aimed at producing a specific product: optimization. Although we are increasingly able to build sophisticated constructs within living cells, the existence of these frameworks does not always correspond with their ability to fulfill their intended purposes efficiently and effectively.

To maximize the amount of FPP produced, Keasling’s team increased the expression levels of the enzymes in the mevalonte pathway (Fig. 1). He also directed FPP away from the sterol biosynthetic pathway by repressing the enzyme responsible for conversion of FPP to squalene (Fig. 1). Although their methods were effective in producing desired products, the optimization of this biosynthetic pathway was limited only to augmenting the expression levels to only the known elements in the mevalonate pathway. Indeed, the researchers indicated that the yeast strain they developed requires furthers optimization to make the drug production system more commercially feasible. What other changes to the yeast strain could enhance product formation? Were the expression levels the researchers chose truly the best for meeting their goals? Could additional changes to other pathways or protein-protein interactions have lead to increases in product formation or decreases in product consumption? Could the enzymes themselves be more efficient in their catalytic activities?

Figure 1: (Ro, 2006 - Permission Pending)

The Theory of Directed Evolution

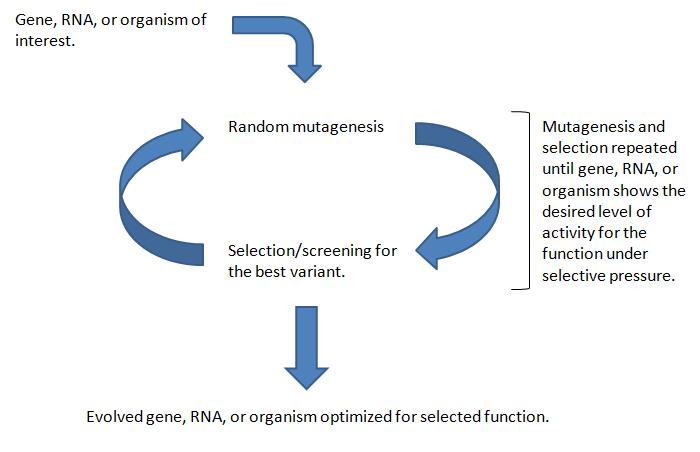

One strategy that has the potential of addressing many of these questions within the context of synthetically constructed pathways is directed evolution. The directed evolution approach uses nature’s selective capabilities to test a large number of variants in a studied organism, pathway, or enzyme to find variants that confer greater efficiency. Directed evolution experiments follow these general steps:

- A large library of variants of the targeted gene, pathway, or cell is generated using methods that randomly change genomic DNA, such as error-prone PCR or transposon integration.

- Screening or selection techniques specific for the function of interest (e.g. higher enzyme efficiency, greater cell resistance to ethanol) reveal the most productive members of the variant library.

- The most productive variant is resubmitted to the genetic randomization and selection processes until the desired result is received - an evolved mutant more adept at the processes it was selected for than its wild-type parent.

One cycle of genomic randomization and selection is called a round.

The power of directed evolution comes from two sources: its nonbiased nature and its capability of probing regions of the cell currently undescribed or beyond the present capabilities of linear modeling and reasoning.

For a retorspective review of the technique, click here.

Proof of Concept: Directed Evolution vs. Rational Modeling in Lycopene-producing E. coli

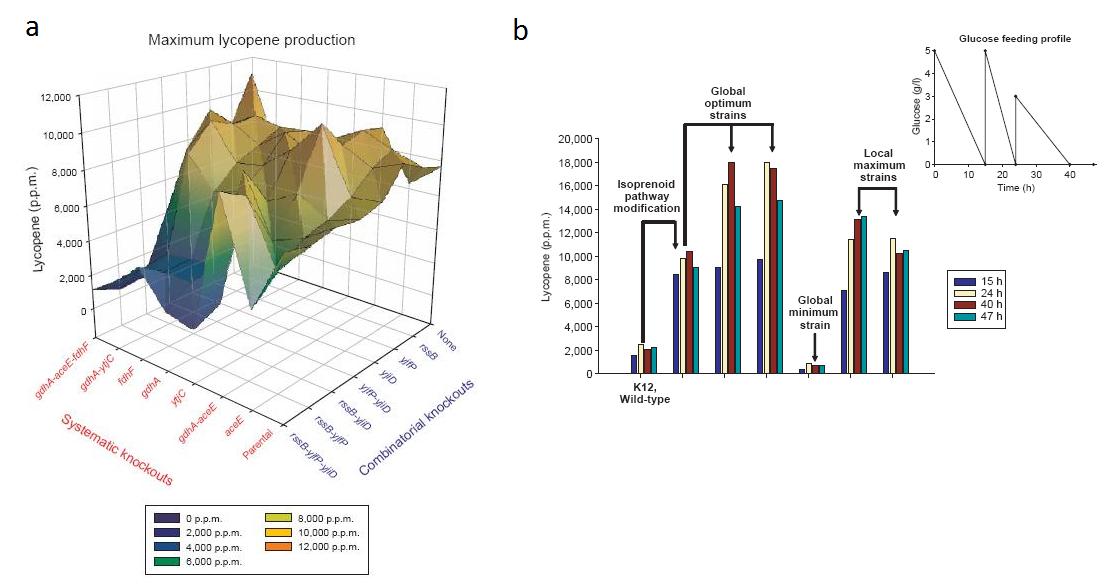

Both of these ideas were recently demonstrated in the work of researchers Hal Alper and Greg Stephanopoulos. Previously, the two researchers had created a strain of E. coli capable of synthesizing lycopene, a carotenoid which naturally occurs in tomatoes but has more recently been incorporated into vitamin tablets for its antioxidant capabilities. The team was interested in how two different sets of gene knockouts, one predicted by computer modeling and the other selected through directed evolution tests, compared in their ability to increase this strain’s lycopene production. They were also interested in whether these two types of gene knockouts would have additive effects and increase lycopene production more if they were expressed together.

To answer both of these questions, the researchers first used a previously described computer model to identify eight gene knockouts that were predicted to increase lycopene production. They complimented these experiments with an in vivo directed evolution test to indentify a second set of knockout sites. This test used transposon integration to create a library of random genome-wide gene knockout strains. The best of these knockout strains were selected through plating, which revealed lycopene production efficiency as a function of red colony color. This directed evolution test selected three gene knockout sites.

By combining all permutations of these three knockouts (one, two, and three gene knockouts) and their parental strain with the eight model-predicted knockouts in all possible ways, the researchers created 64 unique strains of bacteria to examine how randomly selected and systematically predicted gene knockouts might interact to increase lycopene production. Of the two maximum lycopene-producing strains (measured through absorbance of extracted lycopene at 475 nm), one strain had a knockout selected through directed evolution testing (Fig. 2a). Furthermore, this particular knockout strain also showed an earlier peak in lycopene production when compared to the completely stystematically-predicted knockout strain in batch fed culture (Fig. 2b).

(Alper, 2005 - Permission Pending)

Figure 2: The two measurements lycopene production in knockout strains of lycopene producing bacteria. (a) A landscape displaying the 64 strains resulting for all possible combinations of gene knockouts selected through systematic modeling and directed evolution (combinatorial knockouts). Lycopene production for each strain was measured at the end of a 48-h shake-flask fermentation and amount of lycopene produced was quantified through extraction form the cell pellet with acetone and supernatant absorbance at 475 nm. Of interest is global maximum strain ΔgdhA ΔaceE ΔPyjiD, which contains a knockout of the ΔPyjiD gene selected through directed evolution testing. (b) Lycopene production of the best knockout strains in batch-fed culture. From left to right, the K12 strain from which combinatorial mutants were derived, the preengineered parental strain from which the systematically-selected knockout strains were derived, global maximum strain ΔgdhA ΔaceE ΔfdhF, global maximum strain ΔgdhA ΔaceE ΔPyjiD, and the global minimum strain and two local maximum strains from landscape 1a. Of interest is knockout strain ΔgdhA ΔaceE ΔPyjiD (fourth from the left). This strain, which has a gene knockout selected through directed evolution testing, shows the same maximum in lycopene productivity as the entirely systematically-predicted strain ΔgdhA ΔaceE ΔfdhF (third from left), but also shows an earlier peak in this productivity and more sustained lycopene production.

Increases in Sophistication: Three Examples of Directed Evolution Showing Promise for Synthetic Biology

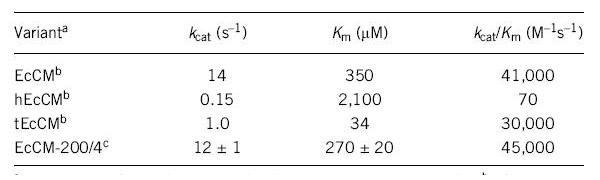

Neuenschwander, M., M. Butz, C. Heintz & D. Hilvert. 2007. A simple selection strategy for evolving highly efficient enzymes. Nature Biotechnology 25(10): 1145-1147.

(Neuenschwander, 2007 - Permission Pending)

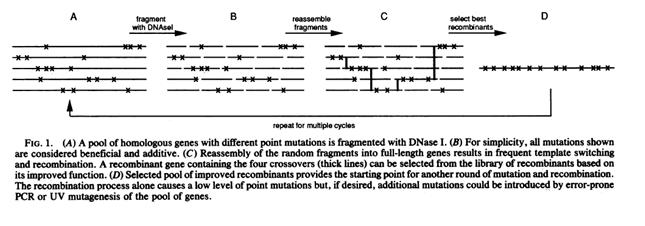

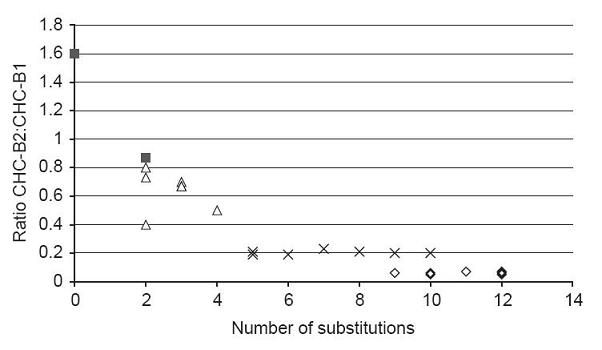

Stutzman-Engwall, K., S. Conlon, R. Fedechko, H. McArthur, K. Pekrun, Y. Chen, S. Jenne, C. La, N. Trinh, S. Kim, Y. Zhang, R. Fox, C. Gustafsson & A. Krebber. 2005. Semi-synthetic DNA shuffling of aveC leads to improved industrial scale production of doramectin by Streptomyces avermitilis. Metabolic Engineering 7: 27-37.

(Stemmer, 1994 - Permission Pending)

(Stutzman-Engwall, 2005 - Permission Pending)

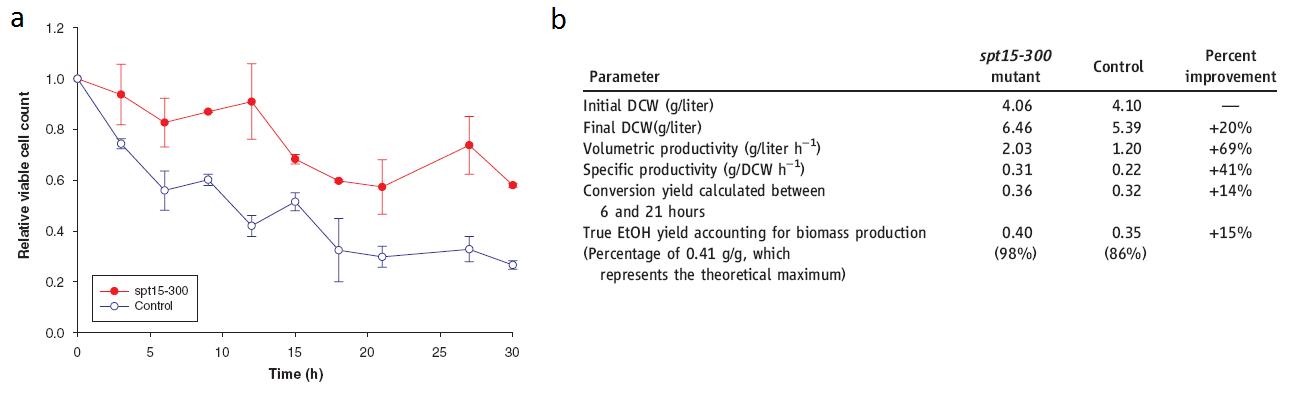

Alper, H., J. Moxley, E. Nevoigt, G.R. Fink & G. Stephanopoulos. 2006. Engineering yeast transcription machinery for improved ethanol tolerance and production. Science 314: 1565-1568.

(Alper, 2006 - Permission Pending)