Difference between revisions of "Directed Evolution and Synthetic Biology - Hunter Stone"

(→Proteins) |

(→Directed Evolution and Synthetic Biology) |

||

| (63 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

====Project Proposal==== | ====Project Proposal==== | ||

| − | My project focuses on the use of random mutations to optimize synthetic pathways. Mathematical modeling of synthetic pathways is a powerful, proven tool to maximize product output. However, recently a series of unbiased strategies using recombinant methods have been shown to further increase product yield. These methods, which | + | My project focuses on the use of random mutations to optimize synthetic pathways. Mathematical modeling and rational engineering of synthetic pathways is a powerful, proven tool to maximize product output. However, recently a series of unbiased strategies using recombinant methods have been shown to further increase product yield. These methods, which have been referred to as directed evolution, have produced powerful new methods and approaches for the synthetic biologist. |

| − | ==Introduction - Optimization and Directed Evolution== | + | ==Introduction - Pathway Optimization and Directed Evolution== |

| − | Researcher Jay Keasling has recently described a genetically-modified yeast strain that produces artemisinic acid, a chemical precursor to the antimalarial drug artemisinin. In these experiments, his team engineered yeast cells to express enzymes in a pathway that converts farnesyl pyrophosphate (FPP), a metabolic intermediate naturally occurring in yeast, into the desired product. Initially, however, this | + | Researcher Jay Keasling has recently described a genetically-modified yeast strain that produces artemisinic acid, a chemical precursor to the antimalarial drug artemisinin (Ro, 2006). In these experiments, his team engineered yeast cells to express enzymes in a pathway that converts farnesyl pyrophosphate (FPP), a metabolic intermediate naturally occurring in yeast, into the desired product. Initially, however, this strain was unable to produce any appreciable amount of artemisin . Keasling’s team had run into a key problem facing many projects in synthetic biology: optimization. Although we are increasingly able to express sophisticated constructs within living cells, the existence of these frameworks does not always correspond with the ability to fulfill their intended purposes efficiently and effectively. |

| − | Keasling’s team chose to address this problem by rationally modifying the metabolism of their yeast strain. Although they were successful in increasing | + | Keasling’s team chose to address this problem by rationally modifying the metabolism of their yeast strain. Although they were successful in increasing product yields, further optimization was required for them to meet their goals. What would be the best approach to increase product yield in this system? Were the changes the already made to the yeast’s metabolism truly the best for optimizing artemisinin output? Could changes in other distantly-related metabolic pathways have also helped to increase yields? Are there presently unknown elements in the cell affecting the new pathway which could potentially be changed? Are the enzymes in the new pathway themselves working at maximum efficiency? |

One technique with the potential to answer all of these questions is directed evolution. | One technique with the potential to answer all of these questions is directed evolution. | ||

| − | == | + | ==Directed Evolution: The Method== |

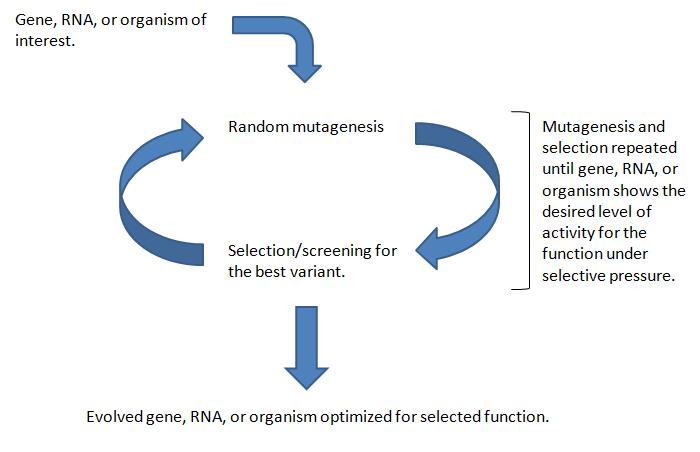

Directed evolution is a method used to create a more efficient mutant of an existing gene, RNA, pathway or cell. The method follows these general steps: | Directed evolution is a method used to create a more efficient mutant of an existing gene, RNA, pathway or cell. The method follows these general steps: | ||

| − | # A library of variants of the targeted construct (e.g. a gene | + | # A library of variants of the targeted construct (''e.g.'', a gene or a cell) is generated through random changes of its genomic DNA. Methods of genetic randomization include error-prone PCR, mutagenic agents like Mutazyme, or random transposon integration. |

| − | # The variant library goes through a process of screening or selection to reveal the most productive members of the library. Selection and screening techniques are specific to desired function of each experiment (e.g. higher enzyme efficiency, greater cell resistance to ethanol). | + | # The variant library goes through a process of screening or selection to reveal the most productive members of the library. Selection and screening techniques are specific to desired function of each experiment (''e.g.'' higher enzyme efficiency, greater cell resistance to ethanol). |

# The most productive variant is resubmitted to the genetic randomization and selection processes. | # The most productive variant is resubmitted to the genetic randomization and selection processes. | ||

# Steps 1-3 are repeated until the desired result is received - an evolved mutant more adept at the processes it was selected for than its unevolved parent. | # Steps 1-3 are repeated until the desired result is received - an evolved mutant more adept at the processes it was selected for than its unevolved parent. | ||

| Line 22: | Line 22: | ||

[[Image:DIRECTEDEVOLUTION.jpg]] | [[Image:DIRECTEDEVOLUTION.jpg]] | ||

| − | + | ==Directed Evolution and Synthetic Biology== | |

| − | + | The power of directed evolution comes from two sources: its nonbiased nature and its ability to test changes in elements of the cell beyond present knowledge and understanding. The method has historically been used to maximize the function of a particular protein. New methods have been developed recently to maximize the function not just of a single protein, but of more complex phenotypes. Using directed evolution to improve both proteins and these more complex phenotypes like enzymatic pathways has tremendous promise for synthetic biology. | |

| − | == | + | ===Optimization of Enzyme Function=== |

| − | + | Many projects in synthetic biology involve introducing foreign enzymatic pathways into microbes to produce a desired product. Examples include yeast cells engineered to produce atremisinin (Ro ''et al.'', 2006) or microbes engineered to produce fossil fuels ([http://www.amyrisbiotech.com/ Amyris], [http://www.ls9.com/ LS9]). The quantity of output from these pathways ultimately depends on the efficiency of the enzymes introduced. However, rational reengineering of these enzymes is an extremely difficult task due to the complexities of protein structure as well as the lack of sufficient knowledge regarding the relationship between protein structure and funtion. | |

| − | + | Two papers describe successful use of directed evolution to improve product yield by augmenting enzymatic function. In both papers, the authors circumvent the laborious task of rational protein engineering by using directed evolution. In addition, the papers describe improvements in genetic randomization and selection to maximize enzyme function. | |

| − | |||

| − | |||

| − | |||

| − | |||

| Line 43: | Line 39: | ||

==="Genome-wide" Directed Evolution=== | ==="Genome-wide" Directed Evolution=== | ||

| + | A second, emerging branch of directed evolution attempts to improve phenotypes regulated not just by an individual gene but by multiple genes across the entire genome. | ||

| − | + | This type of directed evolution provides a method to test changes in many different elements of a cell that make up a system. Attempts at directed evolution on such a scale are relatively new. The following papers describe the use of "genome-wide" directed evolution to improve product yield from complex pathways. So long as improvements can be screened and selected for, these methods might also be applied to improvement and optimization of complex synthetic phenotypes engineered by humans, such as cellular circuitry using an array of [[Logic Gates - Emma Garren|Logic Gates]]. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[Random Gene Knockout to Maximize Product Yield]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[ | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

[[Global Transcriptome Machinery Engineering]] | [[Global Transcriptome Machinery Engineering]] | ||

| − | |||

| − | |||

==Conclusion== | ==Conclusion== | ||

| − | + | Researchers Stutzman-Engwall ''et al.'', Neuenschwander ''et al.'', and Alper ''et al''. have all described successful uses of a general method of engineering called directed evolution to improve desired phenotypes. At no point during these experiments did the researchers draw a model or plan specific changes to genetic code to engineer these phenotypes. Some might say that for this reason directed evolution does not belong within the realm of synythetic biology. At the same time, if synthetic biology is the “engineer’s approach to biology,” then what is an engineer ultimately concerned with except the production of a useful product that meets a need? The research described in the four papers reviewed certainly meets this criterion. Furthermore, the work by Stuzman-Engwall ''et al.'' and Neuenschwander ''et al.'' indicates that directed evolution is, in its own way, becoming an increasingly planned and rational process. Semi-synthetic DNA shuffling allows the researcher to which mutations stay in wheels of genetic randomization and selection, while the “selection vector” described in the work of Neuenschwander et al. allows the researcher to precisely control selective pressure on the enzyme being evolved. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | ''' | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Perhaps the best strategy is to leave the definitions aside. Alper’s team has shown in lycopene-producing ''E. coli'' that directed evolution can work in concert with traditonal synthetic modeling to meet overaching goals. The two methods appear well suited for one another. Directed evolution cannot be used to engineer new and creative permutations of enzymes like in Jay Keasling’s artemisinic acid-producing yeast; however, as shown in these four papers, the method is an effective way to improve existing systems at multiple levels. On the other hand, while synthetic biology can be used to construct complex biological systems, it is not always apparent to the synthetic biologist why what he or she has engineered does not meet optimal models. Directed evolution provides the synthetic biologist with a way of testing and improving entire systems in a nonbiased manner as they try to make synthetic constructs and optimal model agree. | |

| − | + | As these four papers have shown, when directed evolution is applied to synthetic biology, the two methods work together to create interesting, new, and, most importantly, ''optimally-functioning'' pathways. | |

==Works Cited== | ==Works Cited== | ||

Latest revision as of 16:56, 10 December 2007

Contents

Project Proposal

My project focuses on the use of random mutations to optimize synthetic pathways. Mathematical modeling and rational engineering of synthetic pathways is a powerful, proven tool to maximize product output. However, recently a series of unbiased strategies using recombinant methods have been shown to further increase product yield. These methods, which have been referred to as directed evolution, have produced powerful new methods and approaches for the synthetic biologist.

Introduction - Pathway Optimization and Directed Evolution

Researcher Jay Keasling has recently described a genetically-modified yeast strain that produces artemisinic acid, a chemical precursor to the antimalarial drug artemisinin (Ro, 2006). In these experiments, his team engineered yeast cells to express enzymes in a pathway that converts farnesyl pyrophosphate (FPP), a metabolic intermediate naturally occurring in yeast, into the desired product. Initially, however, this strain was unable to produce any appreciable amount of artemisin . Keasling’s team had run into a key problem facing many projects in synthetic biology: optimization. Although we are increasingly able to express sophisticated constructs within living cells, the existence of these frameworks does not always correspond with the ability to fulfill their intended purposes efficiently and effectively.

Keasling’s team chose to address this problem by rationally modifying the metabolism of their yeast strain. Although they were successful in increasing product yields, further optimization was required for them to meet their goals. What would be the best approach to increase product yield in this system? Were the changes the already made to the yeast’s metabolism truly the best for optimizing artemisinin output? Could changes in other distantly-related metabolic pathways have also helped to increase yields? Are there presently unknown elements in the cell affecting the new pathway which could potentially be changed? Are the enzymes in the new pathway themselves working at maximum efficiency?

One technique with the potential to answer all of these questions is directed evolution.

Directed Evolution: The Method

Directed evolution is a method used to create a more efficient mutant of an existing gene, RNA, pathway or cell. The method follows these general steps:

- A library of variants of the targeted construct (e.g., a gene or a cell) is generated through random changes of its genomic DNA. Methods of genetic randomization include error-prone PCR, mutagenic agents like Mutazyme, or random transposon integration.

- The variant library goes through a process of screening or selection to reveal the most productive members of the library. Selection and screening techniques are specific to desired function of each experiment (e.g. higher enzyme efficiency, greater cell resistance to ethanol).

- The most productive variant is resubmitted to the genetic randomization and selection processes.

- Steps 1-3 are repeated until the desired result is received - an evolved mutant more adept at the processes it was selected for than its unevolved parent.

Directed Evolution and Synthetic Biology

The power of directed evolution comes from two sources: its nonbiased nature and its ability to test changes in elements of the cell beyond present knowledge and understanding. The method has historically been used to maximize the function of a particular protein. New methods have been developed recently to maximize the function not just of a single protein, but of more complex phenotypes. Using directed evolution to improve both proteins and these more complex phenotypes like enzymatic pathways has tremendous promise for synthetic biology.

Optimization of Enzyme Function

Many projects in synthetic biology involve introducing foreign enzymatic pathways into microbes to produce a desired product. Examples include yeast cells engineered to produce atremisinin (Ro et al., 2006) or microbes engineered to produce fossil fuels (Amyris, LS9). The quantity of output from these pathways ultimately depends on the efficiency of the enzymes introduced. However, rational reengineering of these enzymes is an extremely difficult task due to the complexities of protein structure as well as the lack of sufficient knowledge regarding the relationship between protein structure and funtion.

Two papers describe successful use of directed evolution to improve product yield by augmenting enzymatic function. In both papers, the authors circumvent the laborious task of rational protein engineering by using directed evolution. In addition, the papers describe improvements in genetic randomization and selection to maximize enzyme function.

Semi-Synthetic DNA Shuffling and Doramectin

A Simple Method for Highly Evolved Enzymes

"Genome-wide" Directed Evolution

A second, emerging branch of directed evolution attempts to improve phenotypes regulated not just by an individual gene but by multiple genes across the entire genome.

This type of directed evolution provides a method to test changes in many different elements of a cell that make up a system. Attempts at directed evolution on such a scale are relatively new. The following papers describe the use of "genome-wide" directed evolution to improve product yield from complex pathways. So long as improvements can be screened and selected for, these methods might also be applied to improvement and optimization of complex synthetic phenotypes engineered by humans, such as cellular circuitry using an array of Logic Gates.

Random Gene Knockout to Maximize Product Yield

Global Transcriptome Machinery Engineering

Conclusion

Researchers Stutzman-Engwall et al., Neuenschwander et al., and Alper et al. have all described successful uses of a general method of engineering called directed evolution to improve desired phenotypes. At no point during these experiments did the researchers draw a model or plan specific changes to genetic code to engineer these phenotypes. Some might say that for this reason directed evolution does not belong within the realm of synythetic biology. At the same time, if synthetic biology is the “engineer’s approach to biology,” then what is an engineer ultimately concerned with except the production of a useful product that meets a need? The research described in the four papers reviewed certainly meets this criterion. Furthermore, the work by Stuzman-Engwall et al. and Neuenschwander et al. indicates that directed evolution is, in its own way, becoming an increasingly planned and rational process. Semi-synthetic DNA shuffling allows the researcher to which mutations stay in wheels of genetic randomization and selection, while the “selection vector” described in the work of Neuenschwander et al. allows the researcher to precisely control selective pressure on the enzyme being evolved.

Perhaps the best strategy is to leave the definitions aside. Alper’s team has shown in lycopene-producing E. coli that directed evolution can work in concert with traditonal synthetic modeling to meet overaching goals. The two methods appear well suited for one another. Directed evolution cannot be used to engineer new and creative permutations of enzymes like in Jay Keasling’s artemisinic acid-producing yeast; however, as shown in these four papers, the method is an effective way to improve existing systems at multiple levels. On the other hand, while synthetic biology can be used to construct complex biological systems, it is not always apparent to the synthetic biologist why what he or she has engineered does not meet optimal models. Directed evolution provides the synthetic biologist with a way of testing and improving entire systems in a nonbiased manner as they try to make synthetic constructs and optimal model agree.

As these four papers have shown, when directed evolution is applied to synthetic biology, the two methods work together to create interesting, new, and, most importantly, optimally-functioning pathways.